The Role of AI in Frozen Food Manufacturing: 11xplay pro, Diamondexch9, Sky exchange bet

11xplay pro, diamondexch9, sky exchange bet: The frozen food industry has seen significant growth in recent years, with consumers looking for convenient and quick meal options. With this surge in demand, manufacturers are constantly looking for innovative ways to improve their processes and meet customer expectations. One technology that is revolutionizing the frozen food manufacturing industry is artificial intelligence (AI).

AI is being used in various aspects of frozen food manufacturing, from quality control to inventory management. By leveraging the power of AI, manufacturers can improve efficiency, reduce costs, and enhance product quality. Let’s take a closer look at the role of AI in frozen food manufacturing.

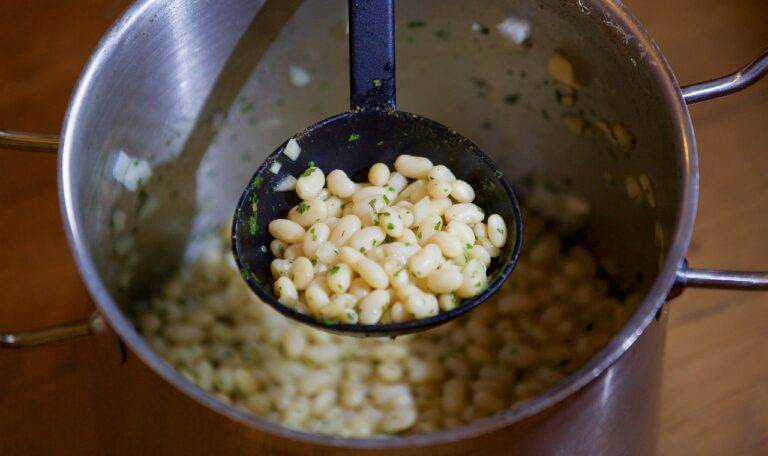

Quality Control

One of the most critical aspects of frozen food manufacturing is maintaining high-quality standards. AI-powered systems can quickly analyze images of food products to identify any defects or inconsistencies. This technology can help manufacturers detect issues early in the production process, allowing them to make necessary adjustments and reduce waste.

Inventory Management

Managing inventory in the frozen food industry can be challenging due to the perishable nature of the products. AI can help manufacturers optimize their inventory levels by analyzing demand patterns, production schedules, and supply chain data. By using AI-powered forecasting tools, manufacturers can ensure they have the right amount of stock on hand to meet customer demand without excess inventory.

Predictive Maintenance

To keep the production line running smoothly, manufacturers need to perform regular maintenance on their equipment. AI can help predict when a machine is likely to break down based on factors such as operating hours and historical data. By implementing predictive maintenance programs, manufacturers can reduce downtime, extend the lifespan of their equipment, and save on maintenance costs.

Product Development

AI is also playing a significant role in product development within the frozen food industry. By analyzing consumer preferences and market trends, manufacturers can use AI-powered systems to create new and innovative products that cater to changing tastes and dietary requirements. This technology can help manufacturers stay ahead of the competition and meet the evolving needs of consumers.

Energy Efficiency

Energy consumption is a significant concern for frozen food manufacturers, as the production process requires large amounts of electricity and other resources. AI can help optimize energy usage by monitoring equipment performance and identifying areas where energy can be saved. By implementing AI-powered energy management systems, manufacturers can reduce their carbon footprint and lower operational costs.

Supply Chain Optimization

In today’s global economy, having an efficient and transparent supply chain is essential for frozen food manufacturers. AI can help optimize supply chain operations by analyzing data from suppliers, distributors, and retailers. By using AI-powered systems to predict demand, track shipments, and optimize routes, manufacturers can ensure their products reach customers on time and in perfect condition.

Conclusion

Artificial intelligence is transforming the frozen food manufacturing industry in remarkable ways. From quality control to inventory management, predictive maintenance, product development, energy efficiency, and supply chain optimization, AI is revolutionizing how manufacturers produce, distribute, and innovate in the frozen food market. By embracing AI technologies, manufacturers can stay competitive, reduce costs, and deliver high-quality products that meet the needs of today’s consumers.

FAQs

Q: How is AI improving quality control in the frozen food industry?

A: AI-powered systems can quickly analyze images of food products to identify defects or inconsistencies, helping manufacturers detect issues early in the production process.

Q: How can AI help optimize inventory management in frozen food manufacturing?

A: AI can analyze demand patterns, production schedules, and supply chain data to help manufacturers optimize their inventory levels and ensure they have the right amount of stock on hand.

Q: What is predictive maintenance, and how does AI play a role in it?

A: Predictive maintenance uses AI to predict when a machine is likely to break down based on factors like operating hours and historical data, helping manufacturers reduce downtime and maintenance costs.

Q: How can AI aid in product development within the frozen food industry?

A: AI analyzes consumer preferences and market trends to help manufacturers create new and innovative products that cater to changing tastes and dietary requirements.

Q: How does AI help optimize energy efficiency in frozen food manufacturing?

A: AI monitors equipment performance and identifies areas where energy can be saved, helping manufacturers reduce their energy consumption and operational costs.